At Pangolim we are very familiar with the conventional calibration apparatus used for the on-site calibration of the client’s base volume in large bore pipe provers.

These types of equipment are relatively large and bulky and are labour intensive to use and associated with extended transit times for equipment to and from client’s site. This attracts increased cost, increased safety hazards, and, increased business risk of equipment damage due to lengthy shipping times and risky locations.

The above has a negative economic impact and especially impacts client’s projects and maintenance schedules.

Often the offshore locations where the larger conventional equipment is needed is not big enough to house the larger equipment and as a result have to be located further away from client’s test site, impacting on testing accuracy and increasing the hazards associated to safety on the clients site.

We have considered the above risks and complications for our clients operations and there is a need within the industry for our much smaller and compact volume proving system that is easily transported to the clients site. Offering higher accuracy and a lower uncertainty of measurement.

A comparison is detailed further below

| Benefit | Pangolim Volume Proving System | Conventional calibration Equipment |

|---|---|---|

| Very light weight and compact delivering fewer shipping charges and shipping delays as this can go on any commercial airline | 250 Kg’s | Typically > 1000/kg’s |

| Improves on testing time up to 60% | Total of 5 hours testing time and achieved in one shift The Pangolim Rig allows for calibrating the onboard Master Meter at the same time of calibrating the volume on the client’s prover loop | Total test time of > 12 hours often testing done over 2 shifts Traditional equipment calibrates the onboard master meter before and after calibrating the volume of the client’s prover loop. Introducing extra unnecessary steps |

| Lower overall Uncertainty of Measurement | The Pangolim Rig is fully automated reducing the chance of technician induced errors of measurement uncertainty | Conventional equipment is heavily dependent on multiple test runs done manually and captured manually by the technician increasing the chance of measurement uncertainty |

| Electrically safer for Zone 1 Hazardous Areas | The Pangolim Rig is compliant for EX Zone 1 Hazardous areas | Traditional equipment is not EX rated and is typically operated under a “Hot Work Permit” increasing the risk to safety on site |

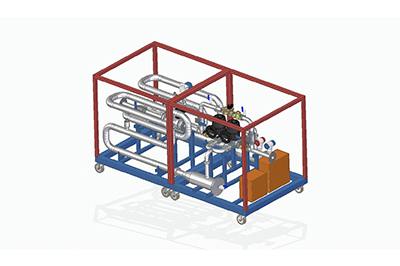

The Pangolim Master Prover loop is a 6inch ball prover with an onboard 3inch Brodie Bi rotor Plus Positive Displacement master meter. Designed to meet the requirements as per API MPMS Chapter 4.2 – Displacement provers.

An EX-certified control panel houses the controls for the rig and distributes the power supply to the onboard instruments and the touch screen HMI for simple automatic activation of proving sequences of the onboard master meter and the client’s prover loop.

Test methods and equipment are selected based on initial consultation with the client, the onsite limitations and the accuracy and uncertainty of measurement required for the clients measurement system.

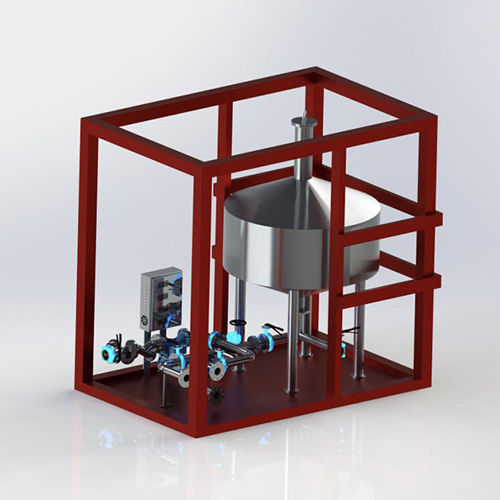

For clientele whose operations are requiring the water draw method of prover calibrations. Pangolim Water Draw equipment is a modular set up that can be customized to any client’s site scenario with a variation of Test Measure volumes to compliment any prover base volume.

The control system such as the water draw control box, pump and stop /start control are all ATEX approved rated for Ee-xd Zone 1 Class II Group B Class T4

Test measures are calibrated within an independent 17025 Volume or Mass calibration lab.

Notifications